How to supply the artwork for your own personalised flow wrapped chocolate bars.

How to supply the artwork for your own personalised flow wrapped chocolate bars.

The process is the same if you want personalised flow wrap or personalised bagging film. Flow wrap and bagging film are both popular types of flexible material used for wrapping and packaging chocolate and confectionery products. They are commonly made from recyclable polythene (PE) or polypropylene (PP). The flexible material can be fully personalised to your design.

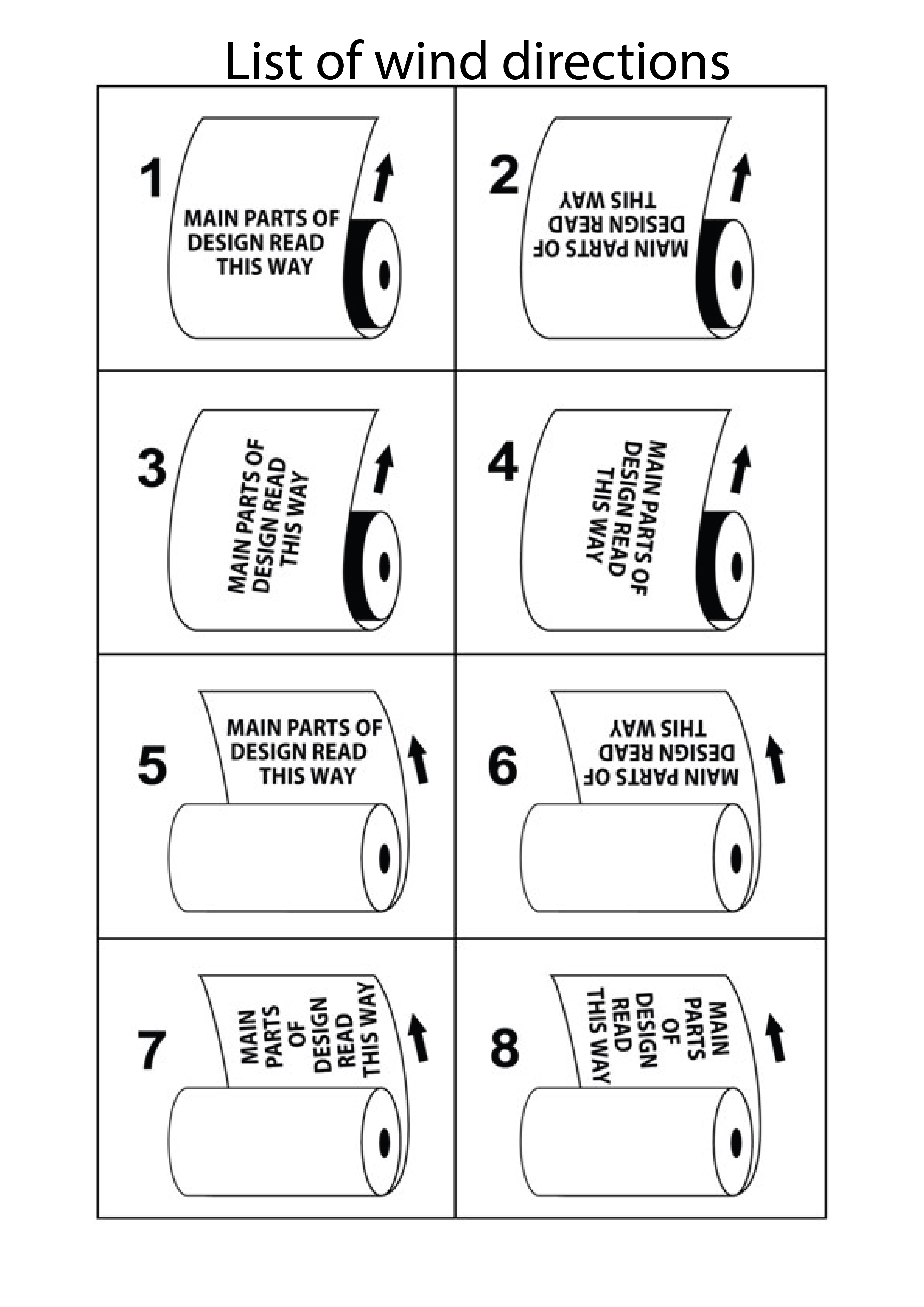

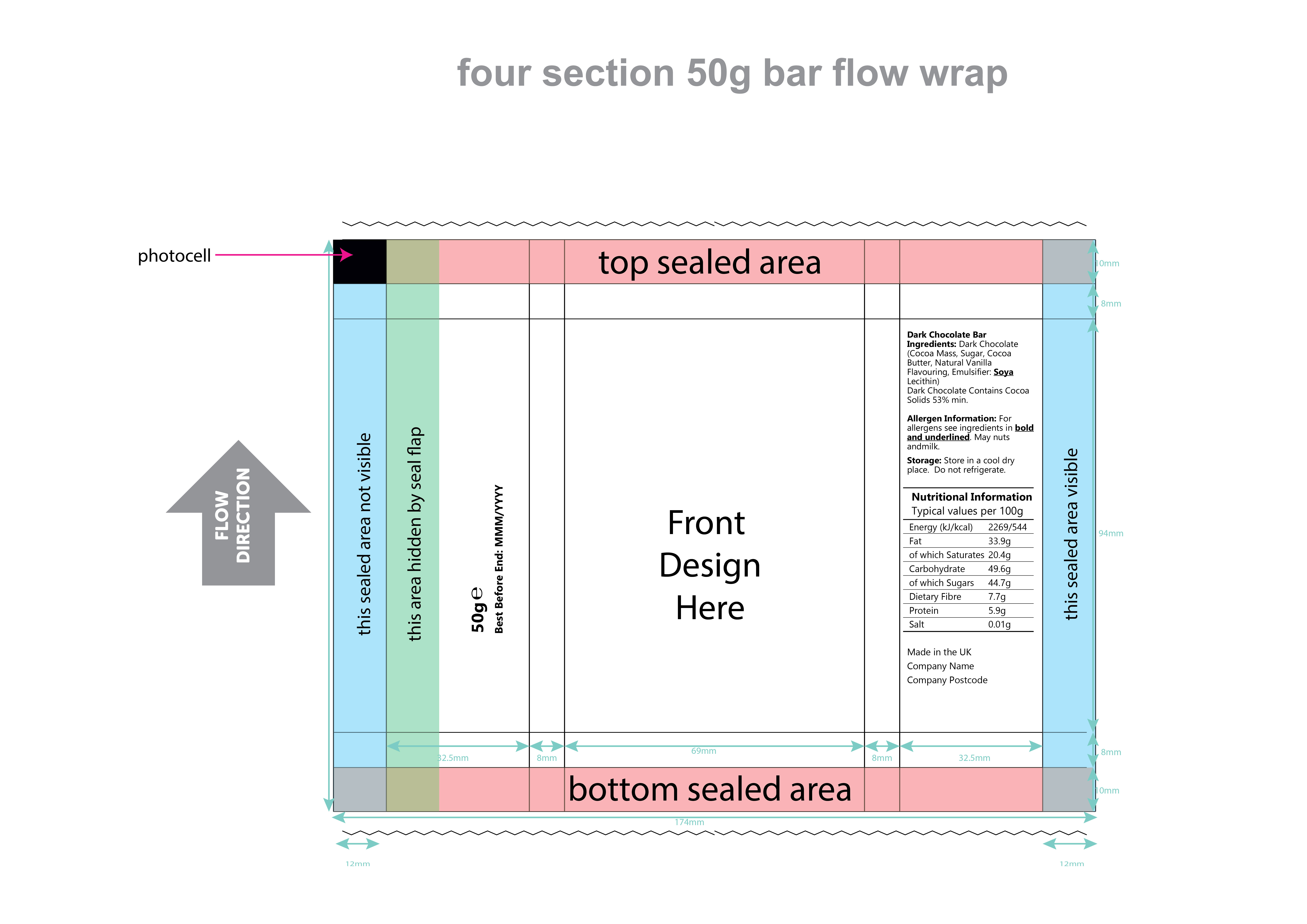

Here’s an explanation of flow wrap and bagging film and the process of putting artwork on a template remembering to include information like the photocell and wind direction.

Bagging film is often known as form-fill-seal. It is a packaging method where a continuous roll of film is formed into a tube around the product and sealed on 3 sides (two longitudinal and one transverse seal).

Flow wrap packaging: Flow wrap packaging is a type of flexible packaging that can be used to create personalised fully sealed packaging. A good example of this is a flow wrapped chocolate bar. The packaging can be made from various materials, in different thickness and with different finishes.

The printer prints your design directly onto the flexible material and then the material is wound onto large rolls. Hames load the large rolls of film onto their flow wrap or bagging machines and the machines form the material around the chocolate or sweets to create wrappers or bags to package the products that we make for you.

Process of supplying artwork for flow wrap packaging:

Technical questions the printer will need to know before the film can be printed::

The process is the same if you want personalised flow wrap or personalised bagging film. Flow wrap and bagging film are both popular types of flexible material used for wrapping and packaging chocolate and confectionery products. They are commonly made from recyclable polythene (PE) or polypropylene (PP). The flexible material can be fully personalised to your design.

Here’s an explanation of flow wrap and bagging film and the process of putting artwork on a template remembering to include information like the photocell and wind direction.

Bagging film is often known as form-fill-seal. It is a packaging method where a continuous roll of film is formed into a tube around the product and sealed on 3 sides (two longitudinal and one transverse seal).

Flow wrap packaging: Flow wrap packaging is a type of flexible packaging that can be used to create personalised fully sealed packaging. A good example of this is a flow wrapped chocolate bar. The packaging can be made from various materials, in different thickness and with different finishes.

The printer prints your design directly onto the flexible material and then the material is wound onto large rolls. Hames load the large rolls of film onto their flow wrap or bagging machines and the machines form the material around the chocolate or sweets to create wrappers or bags to package the products that we make for you.

Process of supplying artwork for flow wrap packaging:

- Ask us for the flow wrap template – this is a die line file that outlines the structure and dimensions of the packaging. Each product or size of product needs its own template

- Set up the artwork file using graphic design software such as Adobe Illustrator. Create a new document with the same dimensions as the template

- Place the template: Import the template into the document as a separate layer making sure it aligns correctly. Lock the template to prevent accidental movements.

- Design the artwork: Put this on a separate layer to the template. Don’t forget to also include information such as ingredients, allergen information, nutritional info, the product weight, include your company contact details and a barcode and any other legally required information.

- Incorporate the photocell eye mark: The photocell is a sensor that detects printed marks or signals. Its important to incorporate the square mark in the design IN THE CORRECT PLACE. The flow wrap film or bagging film is supplied to Hames on large rolls. If the photocell mark is not included in the design then the flow wrap machinery or bagging machinery will not know where to cut the film and we will be unable to use it.

Technical questions the printer will need to know before the film can be printed::

- What is the wind direction

- What is the maximum diameter of the roll of film

- How big should the core of the flow wrap film